Automation

Automation

Packaging labor is an operational cost that often presents a greater opportunity to save money than materials. A frequent solution to reducing packaging labor is simply placing the right packaging system in the packaging operation. The first step is to evaluate the entire packaging process, the number of units packed per hour, the layout of the pack stations, space availability and the number of packers required.

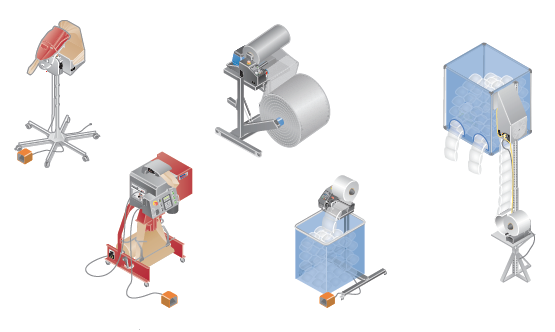

It’s not unusual to achieve 50% labor reductions with a systems approach to packaging. For example, manually wadding paper to fill the spaces in your carton is a labor-intensive method that has been replaced with simple, easy to use paper dispensing systems. The machine wads the paper for you, dispenses the paper directly into the carton via a foot pedal, and really helps speed up the operation.

If you design the right process your able to get more shipments out the door with the least amount of labor. Optimizing your packaging labor may require a completely different packaging material and redesigning the work flow. Keeping your packers at the pack station and delivering the work to them via a conveyor is a great way to maximize productivity.

We specialize in packaging automation and the analysis of the ROI. Materials, processes, design and implementation are all components of a solid automation solution.

Detailed Time Studies

We design and develop ergonomic work stations which put the right materials where you need them. The goal is to minimize the movement or steps required to get the job done. After reviewing your operational challenges, we will custom build fixtures that eliminate lifting, alleviate space constraints or simply help dispense packaging materials faster. Once you improve the work life of the packer by making their job easier you simply get a more productive employee. Enhancing the bottom line and increasing employee satisfaction, now that’s a win-win!